In the realm of fluid control and industrial applications, the choice of valves plays a pivotal role in ensuring seamless operations. Among the myriad valve types available, the jacketed ball valve stands out as a reliable and versatile solution, particularly in industries where temperature control is paramount. We delve into the intricacies of jacketed ball valves, shedding light on their design, applications, and the commendable offerings of Athena Engineering, a distinguished supplier in this domain.

Understanding Jacketed Ball Valves

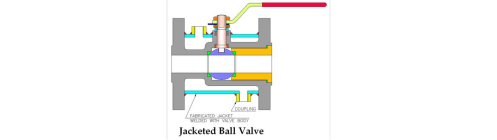

Jacketed ball valves are a specialized type of valve designed to handle applications where maintaining a consistent temperature is crucial. These valves feature a unique construction that includes an outer jacket surrounding the valve body. This jacket facilitates the circulation of a heating or cooling medium, allowing precise temperature control of the process fluid passing through the valve.

The primary component of a jacketed ball valve is the ball itself, which is strategically positioned within the valve body. The ball has a hole through its center, enabling the flow of fluids when aligned with the valve’s inlet and outlet ports. By rotating the ball using the valve handle, operators can regulate the flow, making jacketed ball valves highly effective in controlling various media, including liquids and gases.

Applications of Jacketed Ball Valves

1. Chemical Processing Industries:

Jacketed ball valves find extensive use in chemical processing industries where maintaining specific temperatures is critical for the success of chemical reactions. The ability of these valves to handle corrosive and abrasive materials makes them indispensable in safeguarding both equipment and processes.

2. Pharmaceutical Manufacturing:

In the pharmaceutical sector, precision is paramount. Jacketed ball valves are employed to control the flow of pharmaceutical ingredients with a focus on maintaining sterile conditions. The jacketing ensures that the temperature-sensitive substances remain within the desired temperature range.

3. Food and Beverage Production:

Hygiene is of utmost importance in the food and beverage industry. Jacketed ball valves, with their easy cleanability and resistance to contamination, play a crucial role in regulating the flow of liquids and gases in food processing, ensuring the highest standards of safety and quality.

4. Oil and Gas Sector:

The robust design of jacketed ball valves makes them suitable for applications in the oil and gas sector, where they are often exposed to harsh conditions. These valves excel in handling viscous fluids and maintaining optimal temperatures in pipelines.

5. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems benefit from jacketed ball valves to regulate the flow of hot or cold water, providing efficient temperature control for climate control applications.

Enhanced Design Features of Jacketed Ball Valves

1. Temperature Control Mechanism:

The distinctive feature of jacketed ball valves lies in their ability to control the temperature of the process fluid efficiently. The outer jacket surrounding the valve body serves as a conduit for a heating or cooling medium, ensuring precise thermal management. This capability is particularly vital in applications where maintaining specific temperature ranges is crucial for optimal performance and safety.

2. Dual-Sealing Mechanism:

Jacketed ball valves typically incorporate a dual-sealing mechanism, enhancing their reliability and leak-proof functionality. The primary seal is achieved by the interaction between the ball and the valve seats, while the secondary seal is formed by the close contact between the outer jacket and the valve body. This dual-sealing design minimizes the risk of leaks, making these valves ideal for critical applications where fluid containment is paramount.

3. Versatility in Material Selection:

Athena Engineering’s jacketed ball valves offer versatility in material selection, allowing customers to choose materials that align with the specific characteristics of the handled fluids. Common materials include stainless steel, carbon steel, and exotic alloys, ensuring compatibility with a wide range of corrosive or abrasive substances encountered in various industrial processes.

4. Reduced Heat Transfer Losses:

The jacketed construction of these valves plays a crucial role in minimizing heat transfer losses during fluid flow. By enveloping the valve body in a thermally insulating layer, jacketed ball valves help maintain the desired temperature within the process fluid. This feature is particularly advantageous in applications where energy efficiency and heat conservation are priorities.

5. Ease of Maintenance:

Jacketed ball valves from Athena Engineering are designed with ease of maintenance in mind. The simple construction and minimalistic design contribute to straightforward disassembly and reassembly, facilitating routine maintenance tasks. This characteristic reduces downtime and operational disruptions, enhancing the overall efficiency of industrial processes.

6. Fire-Safe Design:

In industries where fire safety is a critical consideration, Athena Engineering’s jacketed ball valves often come equipped with fire-safe design features. This ensures that the valves maintain their integrity and functionality even in the presence of fire, providing an additional layer of safety to industrial facilities.

Athena Engineering: Elevating Jacketed Ball Valve Solutions

Athena Engineering has emerged as a leading supplier in the valve manufacturing landscape, with a focus on delivering high-quality and customized solutions. The company’s commitment to innovation and customer satisfaction is evident in its line of jacketed ball valves, which stand out for several reasons.

1. Precision Engineering:

Athena Engineering employs state-of-the-art manufacturing techniques to ensure that each jacketed ball valve meets the highest standards of precision. The valves undergo rigorous testing to guarantee optimal performance and reliability in diverse industrial settings.

2. Customization Options:

Recognizing the unique requirements of different industries, Athena Engineering provides customization options for jacketed ball valves. Clients can specify materials, sizes, and other features, allowing for tailored solutions that align with their specific operational needs.

3. Durability and Longevity:

The robust construction of Athena’s jacketed ball valves ensures durability and longevity, even in challenging environments. The use of high-quality materials and stringent quality control measures enhances the valves’ resistance to wear, corrosion, and other forms of degradation.

4. Comprehensive Technical Support:

Athena Engineering goes beyond supplying valves by offering comprehensive technical support. This includes assistance in valve selection, installation guidance, and ongoing maintenance recommendations, fostering lasting partnerships with clients.

As industries continue to evolve and demand higher standards of performance, the significance of reliable fluid control mechanisms cannot be overstated. Jacketed ball valves, with their ability to regulate temperature-sensitive processes, have become indispensable in various sectors. Athena Engineering, through its commitment to excellence, has positioned itself as a key player in providing top-notch jacketed ball valve solutions. As industries navigate the complexities of temperature-sensitive applications, the synergy between advanced valve technology and reputable suppliers like Athena Engineering becomes increasingly crucial for ensuring seamless operations.